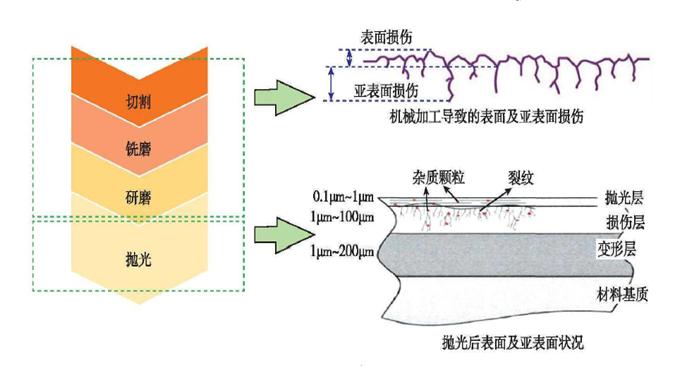

Recently, Zhongke Weijing has made a significant breakthrough in ultrafast laser 3D engraving and milling technology. The company has overcome the technical difficulties of ultra precision machining of complex 3D structural parts with thin-walled spherical shells made of hard and brittle materials. It can achieve the processing of quartz hemispherical resonators without thermal stress and microcracks. The shape and position tolerance of the processed quartz hemispherical resonators is ≤ 2 μ m, the roughness Ra is ≤ 0.13 μ m, and the polishing roughness reaches Ra ≤ 0.04 μ m. This technology can solve the problems of low efficiency, high scrap rate, and low production capacity in traditional mechanical processing of quartz hemispherical resonators, and is of great significance for improving the manufacturing technology of hemispherical resonant gyroscopes in China.

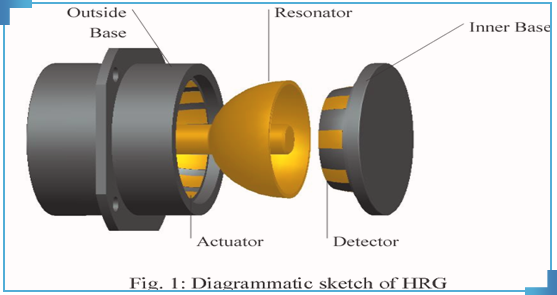

As an excellent inertial navigation instrument, hemispherical resonant gyroscope is widely used in aviation, aerospace, navigation, weapons, transportation, navigation and other fields due to its high precision, high reliability, long lifespan, and resistance to weather and electromagnetic interference. The quartz hemispherical resonator is a complex three-dimensional structural component with a hard, brittle, thin-walled spherical shell. As the core sensitive component of the hemispherical resonator gyroscope, its machining accuracy and vibration characteristics directly determine the working performance of the hemispherical resonator gyroscope.

At present, mechanical processing of quartz hemispherical gyroscopes is widely used in China. However, due to the high hardness and brittleness of the irregular thin shell structure of quartz hemispherical resonators, high requirements are placed on the shape accuracy and position accuracy of the inner and outer spherical surfaces and support rods (at the sub micron level). The efficiency of mechanical processing manufacturing is low, the scrap rate is high, and the processing accuracy is difficult to guarantee. At the same time, the stress generated by mechanical processing will have a significant impact on the performance of the hemispherical gyroscope resonator. Therefore, there is an urgent demand in the market for innovative theories, concepts, methods, and equipment for manufacturing quartz hemispherical resonators.

In response to the above difficulties, Zhongke Weijing has broken the norm and innovatively proposed the use of ultra short pulse laser 3D engraving and milling to solve this problem. Currently, the use of ultra fast laser processing for quartz hemispherical resonators is the first of its kind in China, and there are few reports internationally.

微信公众号

微信公众号

抖音

抖音

视频号

视频号