The femtosecond laser equipment currently in operation in the Zhongke Weijing factory. (Image provided by the interviewed unit)

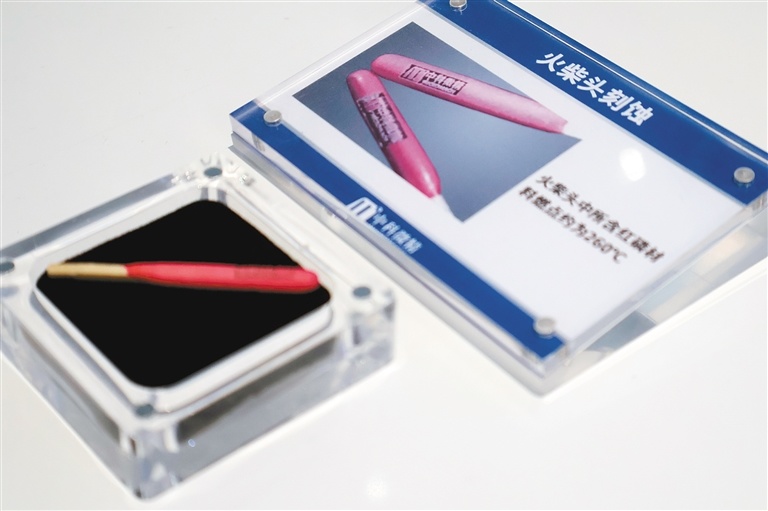

Zhongke Micro Precision Match Head Etching Model Display. (Photo by reporter Liu Xiaohua)

From great to small, there is no outside. Since ancient times, human exploration of space and time has never stopped. Nowadays, for the microscopic world, humans can achieve atomic and molecular scale spatial resolution, and the corresponding motion characteristic time has also reached the ultrafast femtosecond level.

What is the concept of femtosecond—— One femtosecond is one billionth of one second. In the workshop of Xi'an Zhongke Weijing Photon Technology Co., Ltd. (hereinafter referred to as "Zhongke Weijing"), technicians can use laser technology to engrave characters on match heads in femtosecond units.

Founded in 2015, Zhongke Weijing is one of the fourth batch of national level specialized and innovative "little giant" enterprises. As the first enterprise directly invested by the National Manufacturing Fund in Shaanxi, it led and participated in 15 national level major projects, and was the first to develop high-end manufacturing equipment for three-axis to seven axis ultrafast lasers, achieving a breakthrough in China's ultrafast laser precision manufacturing equipment from 0 to 1.

The growth path of Zhongke Microelectronics is not only the path to the growth of Xi'an's photonics manufacturing industry, but also the path to breakthroughs in China's photonics manufacturing technology. Recently, reporters visited Zhongke Weijing, attempting to use its growth microcosm as a slice to see through the booming development momentum of Xi'an's photonics industry.

A beam of light "supports" the construction of a great power

In the first floor exhibition hall of Zhongke Weijing, an engine model stands in the center. Approaching this model, it can be observed that there are many small holes distributed on the hot end components of the engine. This is a complex and irregular microstructure processed by Zhongke Weijing using ultra short pulse laser for domestic commercial aviation new engines.

The aircraft engine is the "heart" of the aircraft, and the hot end components of the engine are an important part of the "heart" of the aircraft. The processing of complex and irregular microstructures is an important challenge that restricts the manufacturing of domestic large aircraft.

So, how to ensure the service life of the hot end components of the engine? A femtosecond laser that can complete fine machining in ultra short time and achieve high surface quality machining is in use.

Taking the processing of matchheads as an example, the low ignition point and small area of matchheads, as well as the ultra short pulse and ultra-high peak power characteristics of femtosecond lasers, enable them to be processed on extreme materials such as matchheads. Unlike the spark splashing in traditional laser processing, the processing speed of femtosecond laser is extremely fast, even too fast to generate heat.

The ultra short pulse laser or femtosecond laser used by Zhongke Weijing is a new type of 'cold processing' method that uses strong field effects to directly ionize materials. The complex microstructures processed by this processing method have better cooling effects, thereby improving the temperature resistance and service life of the engine's hot end components, "said Wang Zi, President of Zhongke Weijing Innovation Research Institute, to reporters.

Excitingly, the three-axis to seven axis series femtosecond laser high-end precision manufacturing equipment developed by Zhongke Weijing has broken the monopoly of similar foreign equipment and technology. At present, technology and equipment from Zhongke Weijing have been applied to large domestic aircraft engines, China's first comprehensive solar exploration satellite "Kuafu-1" and other major national heavy vehicles.

A company "chains" precision manufacturing

Cars speeding on the road, drones hovering and soaring in low air, and detectors silently floating up and down in the water... In Guangxi, the products and technology of Liuzhou Yuanchuang Electronic Fuel Injection Technology Co., Ltd. have expanded from automobiles to industries such as drones, underwater detectors, and high-end medical equipment.

A few years ago, this company specializing in producing automotive fuel injectors was in an awkward situation of being choked by imported equipment. Until Zhongke Weijing applied the femtosecond laser ultra-fine hole machining technology in the aerospace field to the drilling of automotive fuel injectors, it greatly improved the domestic manufacturing capability of this precision component.

In the view of Yang Xiaojun, Chairman of Zhongke Weijing, traditional manufacturing is currently facing deep transformation and upgrading, and one important direction is to shift towards high-end precision machining with higher added value and technological barriers. Ultra fast laser microfabrication technology will greatly enhance the level of traditional manufacturing in this process.

Femtosecond laser can solve the processing bottlenecks of ultra precision, no damage, and no material selectivity that are difficult to achieve in traditional processing methods, and has broad application prospects, "said Wang Zi.

At present, Zhongke Weijing is continuously expanding its ultrafast laser manufacturing technology to civilian fields such as automobiles, healthcare, and consumer electronics. It has incubated four hard technology enterprises, including Zhongke Weixing and Zhongke Juneng, around the upstream and downstream laser industry chain, forming a radiation linkage layout centered on Xi'an, with Guangdong, Beijing, Shanghai and other cities as expansion centers, and German R&D centers as overseas windows.

A path towards industries that focus on "micro" development

Not long ago, good news came from a major national science and technology infrastructure construction: the advanced attosecond laser facility of Xi'an Institute of Optics and Mechanics, Chinese Academy of Sciences passed the feasibility study review and is planned to start construction in October this year.

At present, relatively mature femtosecond pulse lasers are capable of detecting intermolecular motion. However, the dynamic process of electron motion inside molecules occurs at a faster attosecond level. After the completion of this project, it is expected to fill the gap in domestic attosecond laser facilities, promote industrial upgrading and breakthroughs in basic research innovation, "Wang said.

As a hard technology enterprise incubated based on the "Xiguang model", Zhongke Weijing is also continuously advancing the research and development of high-end precision manufacturing equipment for femtosecond lasers. It is understood that Zhongke Weijing Innovation Research Institute will continue to focus on the iterative research and development of laser equipment, with the research direction of completing more precise laser processing in a smaller time scale.

In the future, with the development of light field debugging technology, we will achieve greater breakthroughs in this field. Its significance can be understood as decomposing each beam of light into several pixel points, and at a certain time and spatial resolution, each pixel point can be adjusted, "Wang said.

The so-called 'chasing light' means capturing and utilizing light. In 2021, the Shaanxi Provincial Party Committee and Provincial Government took the lead in implementing the "Chasing Light Plan", with Xi'an High tech Zone as the main carrier, focusing on three major sub sectors: photon materials and chips, advanced laser and photon manufacturing, and photon sensing. The photon industry is regarded as one of the promising new fields and tracks in Shaanxi Province.

In March of this year, the "Action Plan for Cultivating a Billion level Photon Industry Innovation Cluster in Shaanxi Province" was launched, which plans to build a "one core, two wings" around the advantages of photon technology and the foundation of industrial development, and create a photon industry innovation cluster centered on Xi'an and radiating throughout the province.

At present, as the main gathering place for photon industry chain enterprises in the province, Xi'an has initially formed industrial clusters such as photon manufacturing, photon information, and photon sensing. In 2023, the total operating revenue of Xi'an's photonics industry will reach 12.726 billion yuan, and it is expected that the scale of the industry chain will exceed 28 billion yuan this year.

微信公众号

微信公众号

抖音

抖音

视频号

视频号